GSM available: UV film, PET film, non-woven fabric, aluminum foil, PVC film,etc Other customized requirements: anti-skid surface, flame retardant,aging resistance, etc

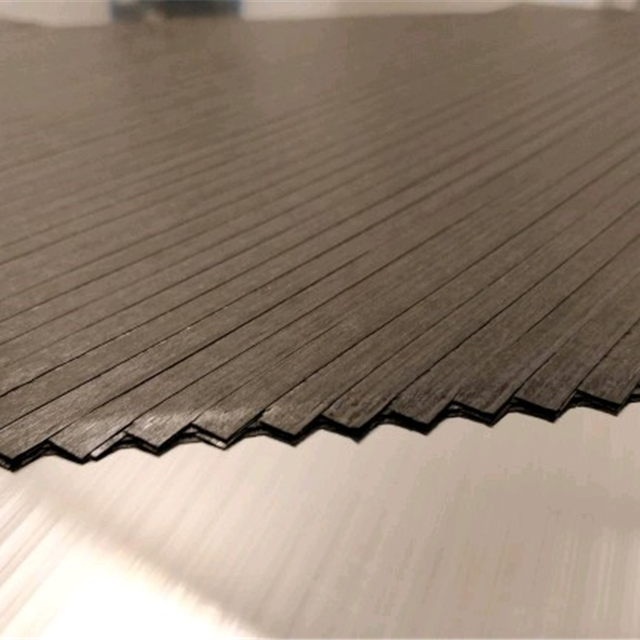

Laminates Performance Datasheet

|

Type |

LM01-P1.0 |

LM02-P1.2 |

LM02-P1.5 |

LM01-P2.0 |

LM01-A3.0 |

|

Materials |

GF/PP |

GF/PP |

GF/PP |

GF/PP |

GF/PA |

|

Fiber Content |

70% |

60% |

60% |

60% |

60% |

|

Laminate Layers |

4 |

4 |

4 |

4 |

10 |

|

Orientation |

0/90/90/0 |

Film+UD +Woven |

Film+UD +Woven |

Film+UD +Woven |

0/90/…/90/0 |

|

GSM (g/㎡) |

1600 |

1500 |

1950 |

2850 |

5000 |

|

Thickness (mm) |

1.0 |

1.2 |

1.5 |

1.5 |

3.0 |

|

Tensile Strength (MPa) |

420-480 |

220-280 |

260-320 |

350-400 |

400-460 |

|

Tensile Modulus (GPa) |

15-17 |

8-10 |

10-12 |

12-14 |

13-15 |

|

Elongation at Break |

3.5% |

3.0% |

2.5% |

2.7% |

3% |

|

Flexural Strength (MPa) |

- |

200-240 |

200-240 |

300-350 |

450-490 |

|

Flexural Modulus (GPa) |

- |

6-8 |

6-8 |

12-14 |

13-15 |

|

Impact Strength (KJ/㎡) |

160 |

80 |

100 |

160 |

190 |

Note:

The above performances are obtained by using the internal testing instruments and environmental conditions of Suijin, on the basis of the relevant standards, which are only used as a reference for customers when designing and using. It is recommended that customers conduct relevant inspection or test on product performance according to specific use requirements.